Innovative craftsmanship:

leather excellence

Innovative craftsmanship:

leather excellence

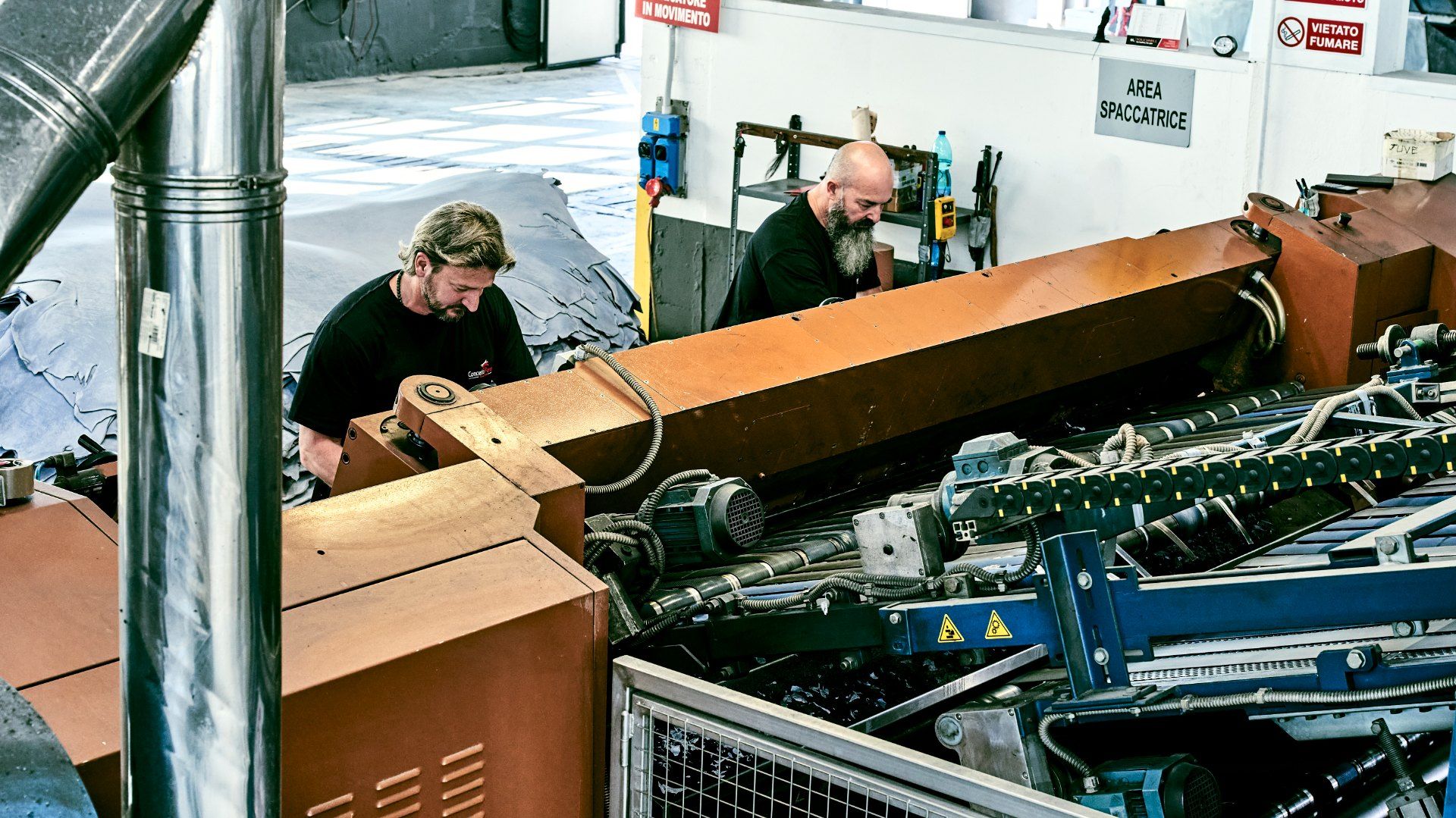

Renowned for its high quality, innovation and focus on sustainability, Conceria Ferrari uses advanced tanning techniques such as wet blue, metal-free and chrome-free tanning. Its two plants blend traditional craftsmanship with cutting-edge technology. Each production step is carried out with precision, to ensure impeccable results. Customisation lies at the heart of the company’s approach, offering tailor-made solutions, as well as a wide range of articles to meet even the most specific requirements.